Shaftwall

TELLING® C-T Shaftwall Framing Components

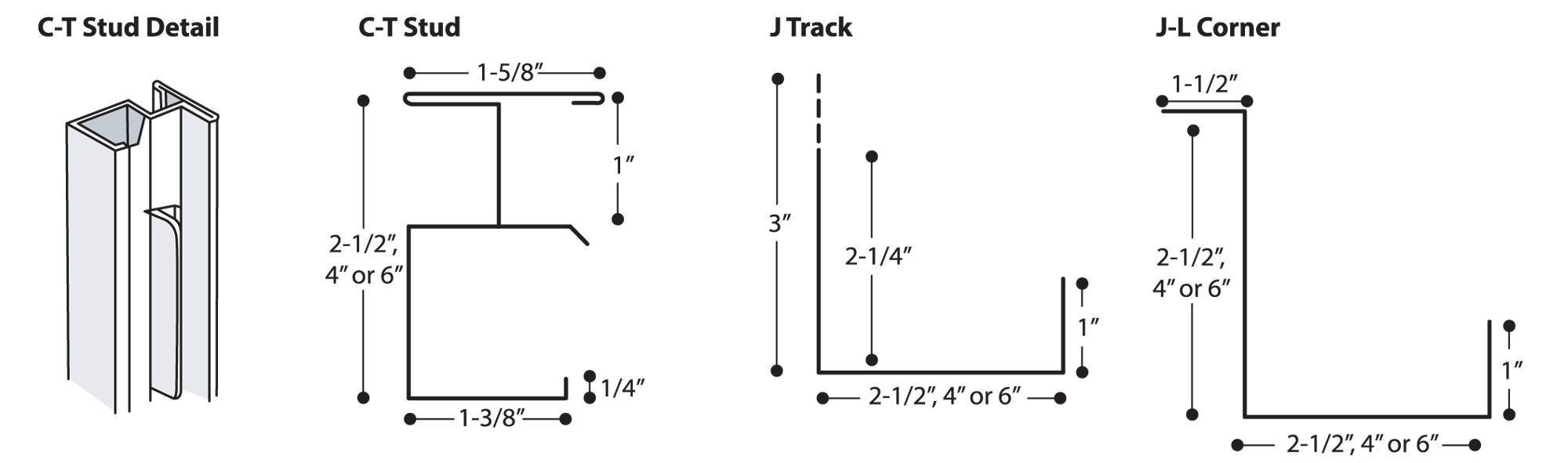

The two primary framing components in Shaftwall framing is the liner board (Example: DensGlass Ultra Shaftliner) and C-T Studs and J tracks, manufactured by TELLING® Industries from galvanized steel that meets the requirements of ASTM A 653 and A 924.

The 2-1/2” steel framing system retains the popular 3-1/2” wall thickness with a two-hour fire rating to accommodate standard door framing dimensions. The Series 620 stud offers a unique feature — slotting in the web of the stud. Tests have demonstrated that these slots effectively improve resistance to thermal and noise transmissions.

The 2-1/2” stud provides a 1-1/2” air cavity for services. Studs are friction-fitted between top and bottom J- tracks. Use J tracks for all closure details, including duct and door openings, abutments, intersections, etc. No other special metal components are required.

The data relating to fire- and sound-tested assemblies is based on the characteristics, properties and performance of materials and systems obtained under controlled test conditions as set forth under the appropriate ASTM standard, such as E 119 (fire),E 90 (sound) or E 72 (structural).

Engineered for durability, our systems withstand the air-pressure surges of high-speed elevators as well as the lateral impact of stairway doors.

RECOMMENDATIONS

- Use a fastening plate to secure the J track whenever fasteners are closer than 4” to the edge. Setting the plate at the time of

- Cut C-T, C-H or I studs 3/4” less than the height of the opening.

- Cut 1” DensGlass Ultra® Shaftliner panel 3/4” less than the height of the opening.

- In structural steel-frame construction, install J track sections before applying spray-on fireproofing.

- Items to be anchored to the wall (cabinets, sinks, handrails, etc.) should be fastened to the C-T, C-H or I studs or to plates secured behind

or between layers of 1/2” ToughRock® Fireguard® C gypsum board. (See illustration on page 12.) - Joint compounds should be applied at ambient temperatures above 50°F (10°C) with adequate ventilation.

- Use Type S screws for 25-gauge steel framing. Use Type S-12 screws for 20-gauge (or heavier) steel framing.

- It is important that the job structural engineer approves the type, size and maximum spacing of track fasteners to meet the design load requirements.

concrete construction will avoid spalling by mechanical fasteners.

- AISI North American Specification [NASPEC] S100-07 with 2010 Supplement

- IBC 2006, 2009, & 2012 Compliant

- Non-Structural framing is produced to meet or exceed ASTM C645, A653, and A1003.

- Member of the Certified Steel Stud Association

Building Code Compliance

Georgia-Pacific Gypsum shaftwall/stairwell enclosures meet the requirements of building codes of major jurisdictions throughout North America.

Easy Installation

Because shaftwall assemblies are built from one side only, there’s no need to access the inside of the shaft. The TELLING® C-T Stud and J-Track steel framing members go up quickly. Most configurations require only two steel components and two types of gypsum board. That makes our systems ideal for furred chases and interior partitions where fire ratings are required for exterior walls and access is restricted.

RESPONSIVENESS, SERVICE, QUALITY

RESPONSIVENESS, SERVICE, QUALITY